Plastics

What are Plastics?

Plastics are synthetic or natural organic materials that can be molded, extruded or rolled into various shapes or spun into fibers. They can also be used to make adhesives, sealants, coatings, and paints among many other products. They are either amorphous or semi-crystalline solids or highly viscous liquids that consist mainly of polymers that are made up of a large number of repeating structural units (monomers) chemically bonded to each other. The oldest plastics were derived from plants and animals. Today most natural plastics have been largely replaced by synthetic plastics, which can be divided into two major classes:

- Thermoplastics - remain plastic after molding and can be reshaped

- Thermosets - become insoluble after heating and/or mixing with hardener

Thermoplastics remain plastic after molding and, therefore, can be repeatedly melted and solidified by heating and cooling. Generally, no chemical changes take place during molding. Thermosets, on the other hand, are converted to chemically cross-linked polymers after heating and/or mixing with hardener, and, therefore, can neither be remolded nor reprocessed (recycled).

Depending on the composition of the plastic and on the structure of the polymer(s), plastics can be flexible and ductile or hard and strong. Due to their relatively low cost, ease of manufacture, versatility, good chemical and environmental resistance, they are used in a vast and ever-expanding number of products, ranging from plastic bottles to spacecrafts and have displaced many traditional materials such as wood, paper, leather, metal, glass, and ceramics.

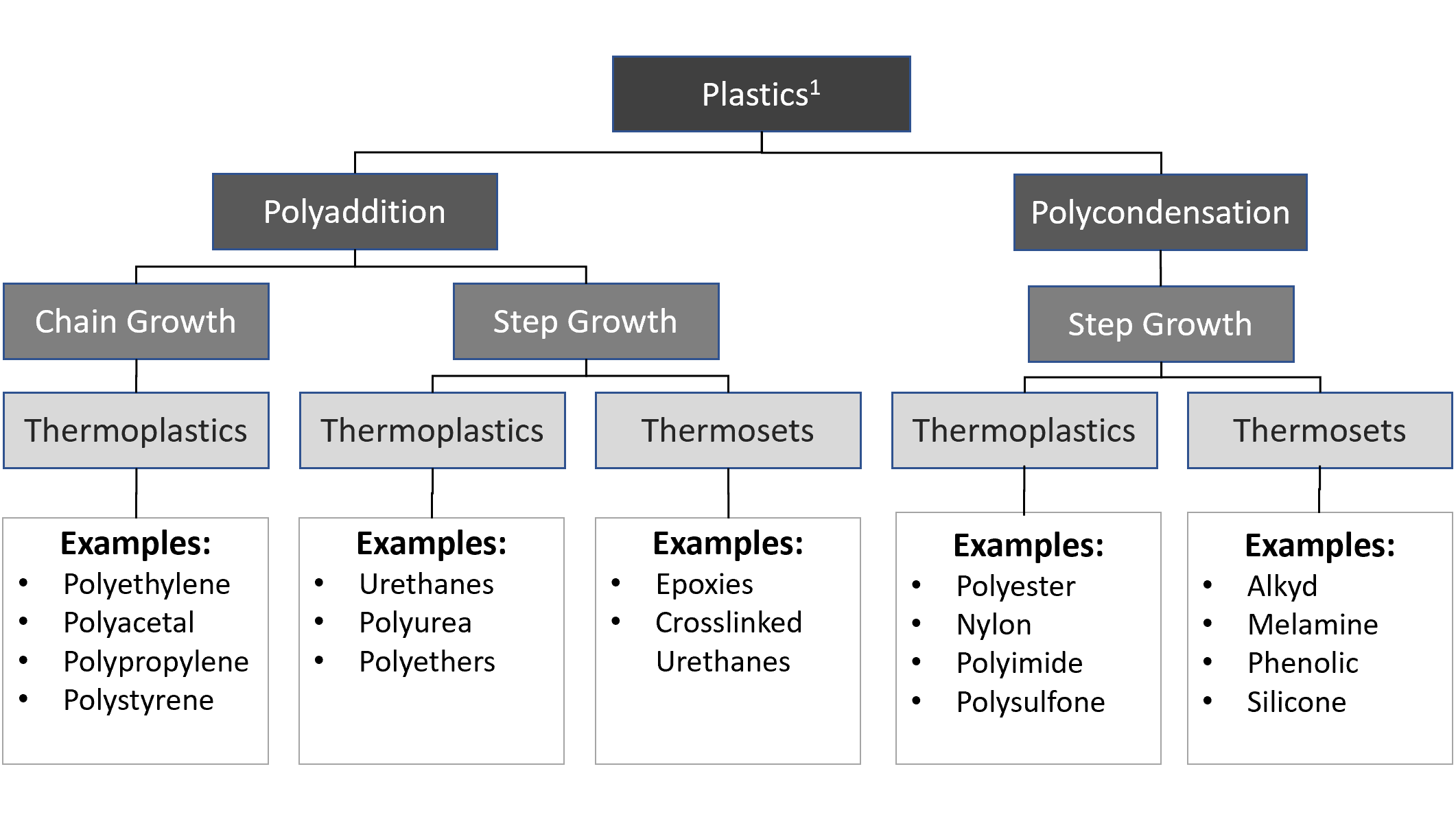

Plastics can be classified in many ways that reflect their chemical makeup, properties, polymerization process, uses, or source:

Classifications based on structure: linear, branched, or crosslinked polymers.

Classifications based on source: natural, synthetic, or semi-synthetic polymers.

Classifications based on properties: thermoplastics, elastomers (rubbers), or thermosets.

Classifications based on polymerisation processes: chain-growth or step-growth polymers

Classification based on uses: plastics, rubbers, fibers, foams, films, coatings, and adhesives

The most important plastics in order of demand (production volume) are polyethylene (PE), polypropylene (PP), polyvinyl chlorides (PVC), polystyrene (PS), polyethylene terephthalate (PETE), and polyurethane (PUR).

The properties of plastics can be altered considerably by incorporation of additives and by the manufacturing process. The most important additives are fillers, colorants, flame retardants, stabilizers, plasticizers, lubricants, and blowing agents. Fillers are often added to lower cost and/or to increase the stiffness, whereas plasticizers have the opposite effect. Stabilizers are added when the plastic has to be protected against degradation by heat, UV light, and oxygen/ozone.